Woodwork has not only been limited to hobbyists but also the professional when the carving or designing proved to be fruitful in business. Through the help of drum sanders, it became a much convenient option to produce on a large scale. These machines improve the consistency and saves a lot of time. Plus, the digital readouts in new technology, appear to bring the quality standards on a whole new level. David Rose believes that though there is a wide range of variety available in the market, one must know that these heavy machines may get damaged during shipping.

So, the purchase should be done by renowned supplier and the selection of design should be appropriate keeping the airflow, dust collection and feed rate in check. There are many kinds of drum sanders like open, closed, single and double but the purpose defines the suitable option that can be opted. There are all kinds of models available in the market for benchtop sanders but the best one of them is,

- Jet JWDS-1020: It resembles a medium drum sander as it is portable based on the size but the feature which improves the mobility is worktable that is parallel and adjustable with the dial. It can sand wooden boards that come with a thickness range of 3 to 20 inches.

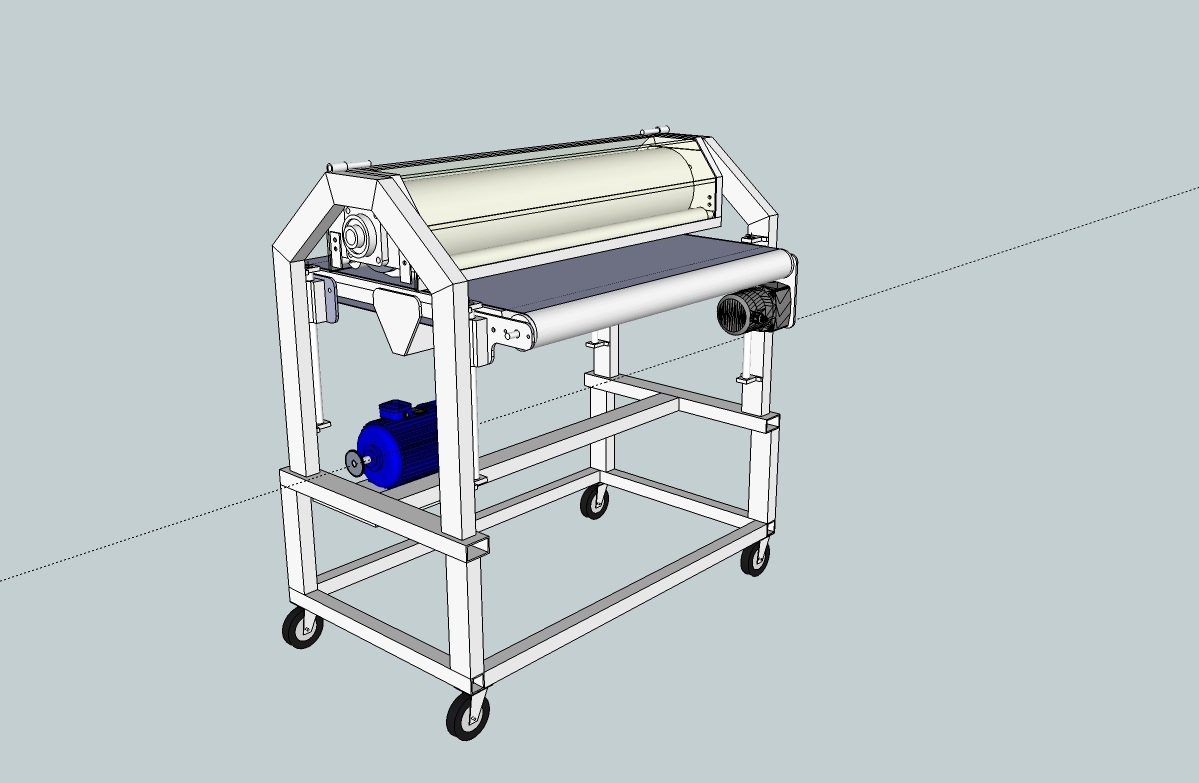

In the aluminum model, a cooling mechanism is installed to protect the drum from heat damage. Also the conveyor belt or table is ductile and one can control the speed based on variable feed rate.